CTO Guide: Machine Vision

Powered by a combination of software and hardware, Machine Vision can improve an organization’s efficiency and operations. MV systems have been around since the 50s, and their use spans industrial and non-industrial areas alike.

Machine Vision sits in the realm of AI and robotics and is tightly connected with obtaining and processing images technology. In this post, we shall look at MV components, techniques, and areas of application. We will also briefly explain the difference between Machine Vision vs. Computer Vision.

To start, let’s consider the anatomy of a Machine Vision system.

Machine vision system components include:

- One or several digital or analog cameras;

- Sensors;

- Processor;

- Frame-grabber;

- Input/output equipment or communication channels for reporting results;

- Light sources like LED, fluorescent or halogen lamps.

- Software for image processing and detection of patterns;

What does Machine Vision do?

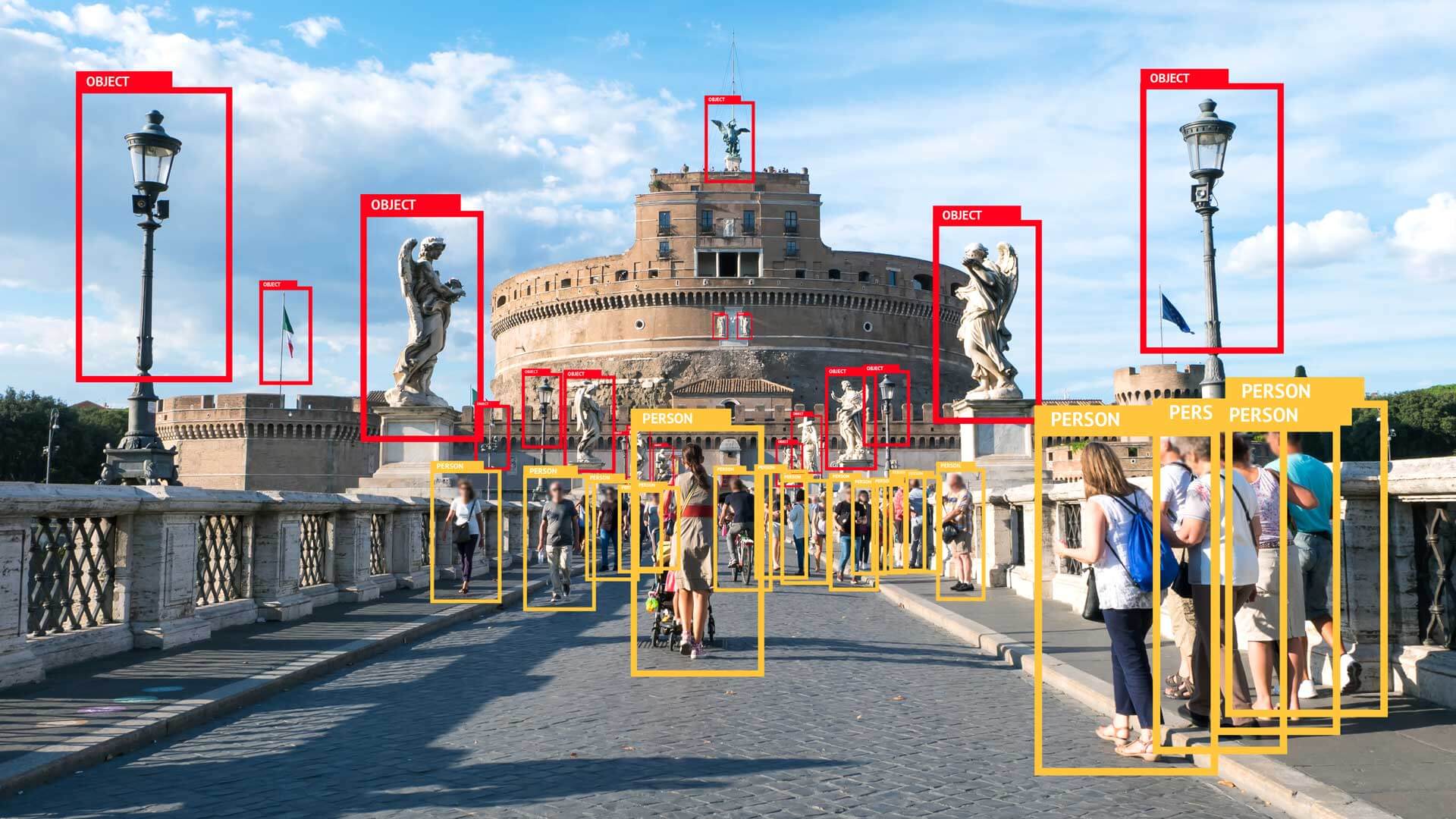

Recognition

A classic computer vision task is determining whether video data contains a particular object, feature, or activity. The best way to solve this task is to bring in a human, given that technology often fails at recognizing objects in odd situations. Machine Vision fares well at recognizing predefined and familiar objects.

Identification

It means identification of an object belonging to a particular class, as in a human face, fingerprint, or vehicle.

Detection

Checking data for a specific object. Detection is based on relatively simple and fast calculations. It is sometimes applied to find minor areas in an image, which are further analyzed using more resource-intensive interpretation techniques.

Text recognition

It has several subsets. One is the search for images by content. It lets you find pictures that have specific content. The second is position optical character recognition. It assumes the recognition of characters in printed or handwritten text. It’s usually for translation into a text format that is most convenient for editing or indexing.

Motion estimation

It’s is the process of determining motion vectors that describe the transformation from one 2D image to another, usually from adjacent frames in a video sequence.

Scene recovery

Scene recovery assumes 3D recovery from several images or a video. The simplest ones are dots in three-dimensional space, whereas more sophisticated methods reproduce a full 3D model.

Image recovery

The task of image recovery is eliminating noise like motion blur or sensor noise. The simplest way here is to apply filters. Achieving greater image recovery levels requires prior video analysis to detect structures and then use filters based on this information.

Optical flow analysis

It includes the analysis of pixel movement between images to recover them. Optical flow analysis is performed through several tasks in which a series of images are processed to estimate every dot’s motion speed within the image or a 3D scene. An example of such can be vehicle motion tracking.

What are image processing techniques?

Pixel counter

It assumes counting the number of light or dark pixels. With the pixel counter, you can select an area on the screen (for example, an area containing faces of people passing by). The camera will immediately respond with the number of pixels in the area of your choosing.

Binarization

This technique converts a grayscale image to white and black pixels. The values of each pixel are conventionally coded as “0” (the background) and “1” (the foreground).

Segmentation

The technique to find and/or count parts. The purpose of segmentation is to break down an image’s representation to streamline its analysis.

Image segmentation is commonly used to highlight objects and boundaries within images. It assigns labels to each pixel so that pixels with similar labels will have common visual characteristics.

As a result, image segmentation breaks the image into multiple segments that make a whole image if put together. All pixels in one segment will have a common characteristic or computed property like color, brightness, or texture.

Reading barcodes

A barcode is a machine-readable representation of numerals and characters applied onto packages or other surfaces. In machine vision, barcodes are used to decode 1D and 2D codes developed for machine-reading and scanning.

Optical character recognition

OCR is an automated text reading like serial numbers. This type of recognition is used to convert hard copies into digital form, automate record-keeping systems, and more. It also helps edit text, look for words and phrases, make the text more compact, as well as apply digital translation, formatting, and text-to-speech conversion.

Machine vision vs. Computer vision: What’s the difference?

These technologies are closely related because machine vision is a subset of computer vision. The main difference is that MV systems are tethered to a computer and enabled by software while computer vision works without a machine. Computer vision is more powerful since it can analyze digital real-time data from sensors and motion detectors, not merely from images or videos.

Machine vision: Applications in business

Machine Vision systems are designed for quality control, identification, inspection, instructing, and more. Several examples include:

Fixing flaws in production lines. Machine vision can not only identify flawed items but also identify the source of the flaws so they can be rectified.

Agriculture. MV systems detect and guide robotic harvesting machines to the grapes’ exact location on the vine so that they can harvest without grapes loss. They also can be used to detect weeds and find damage caused by pests or insects.

Product tracking. MV makes it simple to track product serial numbers, ingredients, expiration dates, and more.

Management and control of inventory. Thanks to its property of reading barcodes and labels, MV is irreplaceable when it comes to manufacturing and inventory control. The systems help to ensure the right components are added to the products on the assembly line.

Safety. Machine vision can control devices, automating production processes. That increases efficiency and makes the workplace safer as it eliminates the need for people to be in dangerous areas.

As Machine Vision advances, the use cases for this technology will continue to grow.

Recommended articles